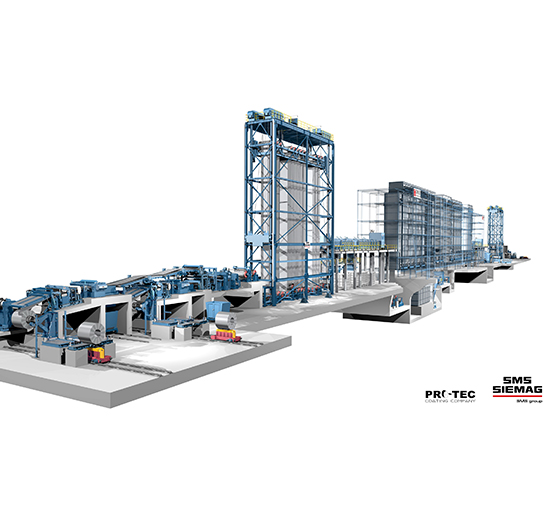

PRO-TEC Steel Nickel Flash Line

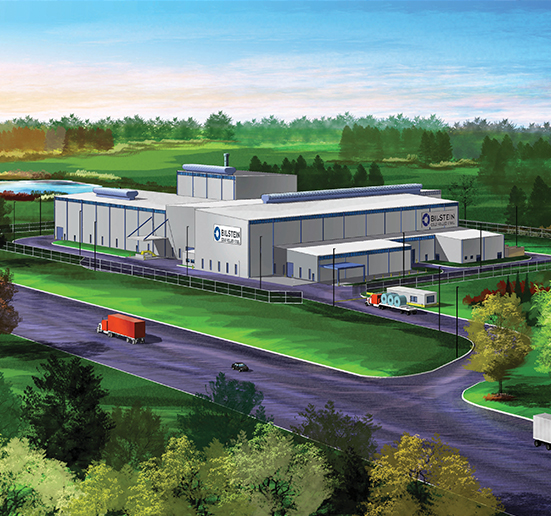

Leipsic, OH

Structural

Metals

German equipment giant SMS Siemag contracted GSE to provide the structural engineering for the design and installation of the steel structures supporting their process equipment, including the vertical entry looper, exit loopers, cleaning section, nickel flash section, continuous annealing, inspection and recoiling equipment. The line produces almost 500,000 tons per year of steel strips for ultra-high-strength structural automotive components, improving vehicles’ safety while reducing their weight. The annealing process and special cooling strategies with exceptionally high cooling rates reduce strain hardening from the rolling process, enabling the sophisticated mechanical properties of the material to be set precisely as required.