This historic property was transformed into a multi-family condominium complex. GSE provided plans and specifications to execute the construction of converting it to a 10-unit complex. GSE’s scope of work included an initial site survey and measurement of existing conditions, layout of the units, HVAC design, structural design, plumbing design, electrical and lighting design, egress and passive fire protection design, and fire detection and suppression design.

Service: Fire Protection Engineering

DaikyoNishikawa

GSE teamed with Kajima Building and Design Group to provide all civil, structural, fire protection, and life safety design for DaikyoNishikawa’s new 295,000-square-foot manufacturing facility in Huntsville, AL. The facility supplies plastic automotive parts to support the Mazda Toyota Manufacturing assembly plant in North Alabama.

Mobile Container Terminals

GSE partnered with Han Padron and Associates (HPA) to design the 100-acre container port on a prepared site. GSE’s project scope included the design of all site utilities (water, sewer, stormwater, electrical, and fire water), administration and maintenance buildings, assorted site structures, site lighting, fire protection design, and construction assistance. GSE oversaw all communication with local governmental agencies and utilities.

Lenzing Fiber

GSE provided all front-end design services for the planned expansion to Lenzing Fiber’s existing facility in Axis, AL. The expansion is expected to more than double current production levels to a total capacity of 140,000 tons annually. GSE’s scope includes all foundations, steel framing, industrial systems, medium voltage distribution, process piping and fire protection system design.

Oceaneering

Oceaneering provides engineered services and products primarily to the offshore energy industry and focuses on deepwater applications. GSE provided planning, design, and construction supervision for a new undersea pipe umbilical facility built on a brownfield site. The project’s scope included renovating a 165,000-square-foot manufacturing space with two 50,000-square-foot circular buildings designed to spool pipe umbilicals. Detailed design included the manufacturing facility, spooling building, guard building, and gate. Site and utility design included grading, paving, storm drainage, fire water, domestic water, sewage, electrical, and communication lines.

Temporary Inmate Housing

The Templeman III and IV jails were demolished in 2007 due to damage sustained from Hurricane Katrina. GSE provided a complete engineering design for phase II of the new Correctional Complex Plan, a 500-bed inmate housing facility built in New Orleans, LA, funded by FEMA. The 40,000-square-foot medium security facility consisted of four identical inmate buildings, a two-story visitation and staff building, and outside recreational areas. Scope of work included project management of the civil design and survey coordination along with structural, fire protection, electrical and mechanical engineering design.

NAVFAC

The Lakeside Building, which obtained LEED Silver Certification, is a two-story structure totaling approximately 200,000 square feet on a 37-acre site. The building includes housing and support facilities for service members while ships are outfitted at Ingalls Shipbuilding in Pascagoula. The design included residence, exercise, food service, administration and utility spaces for this design-build project. The scope of work included a complete sprinkler system, a brick masonry exterior and a new asphaltic roof. Utility space design included domestic and fire water services, sanitary sewer connection, electrical and gas service, mass notification systems, storm drainage and a water quality system. The building design also included precautions for flooding, as Hurricane Katrina flooded the facility’s first floor in 2005.

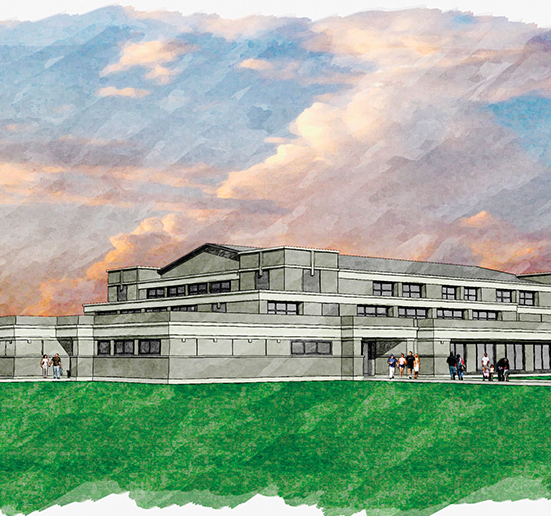

Community Safe Room

GSE provided complete engineering services for the community and recreation center planned for construction at Gay-Lemon Park in Ocean Springs, MS. The ten-acre site houses soccer and baseball fields. The scope of work included structural, mechanical, electrical, civil, and fire protection design for the 18,000-square-foot facility. To ensure the facility could serve as a storm shelter, GSE designed the building to withstand 200 mph winds in accordance with FEMA 361.

Eglin Air Force Base

EOP Processing and Storage facility consolidates operations, support, wing plans, emergency operations and command post facilities to direct functions associated with the Combat Search and Rescue Mission on Moody AFB and geographically separated units. The EOD Barracks building is a three-story structure totaling 174,000 square feet and constructed as a design-build project. GSE’s design included the building’s fire alarm and mass notification systems. The design included a fully sprinkled building with a brick masonry exterior. Other features included DoD Antiterrorism Standards, comprehensive interior design, landscaping, commissioning, and LEED Gold Certification.

BAE Systems

GSE provided a fire code compliance evaluation of all structures on this site. After completing the preliminary assessment, the project scope included updating all non-compliant fire protection and life safety measures. Updates to fire suppression and water supply corrections, new code applications, wet and dry sprinklers, fire main and hydrant layout, fire alarm systems and egress corrections were all deemed necessary updates to the facility in order for the system to be code compliant.