This 10,000-square-foot outpatient oncology center provides care for patients throughout the Mississippi Gulf Coast. GSE provided this facility’s civil site, structural, mechanical, electrical, plumbing and fire protection design. Services site utilities, paving and grading, drainage design, shallow foundations, lighting controls, fire alarm, deep foundations, HVAC systems, panel boards, data/telecom, low voltage, medical gas, transformers and a hazardous exhaust system.

Service: Mechanical Engineering

Chili’s Restaurant

GSE partnered with ANF Architects to provide engineering design for various Chili’s restaurants. New restaurants opened in the following cities: Auburn, Madison, Mobile, Fultondale, Decatur, Gadsden, and Montgomery, AL, and also in Madison, MS. Each restaurant was a 5,500-square-foot new prototype restaurant for Chili’s. GSE’s scope of work included structural, mechanical, electrical, civil site and fire protection design. Services included master planning, shallow foundations, HVAC systems, plumbing, drainage design, fire alarm, data/telecom, low voltage, grading and paving, lighting controls, load-bearing masonry and load-bearing timber.

Walk-On’s Sports Bistreaux

GSE provided engineering services for multiple Walk-On’s locations in recent years, helping this once-local restaurant grow into a multi-state chain. Civil, Structural, Mechanical, Electrical and Fire Protection design services were provided for the Site Plan Development. Other services included stormwater modeling, site utilities, ventilation systems, shallow foundations, steel framing, HVAC systems, medium voltage, fire alarm, plumbing, lighting control and data/telecom. A specialized HVAC design was also provided for a porch area with roll-up garage doors.

Lighthouse Condominiums

The Lighthouse Resort is an oceanfront condominium located on the beaches of Gulf Shores, AL. GSE’s scope of work included mechanical, electrical, plumbing and fire protection design for this 25-story multi-family resort. Services included HVAC systems, ventilation systems, plumbing, low voltage, lighting controls, fire alarm, bid assistance, panel boards, fire pumps, transformers, data/telecom, water supply, construction inspections, lightning protection and stairwell pressurization.

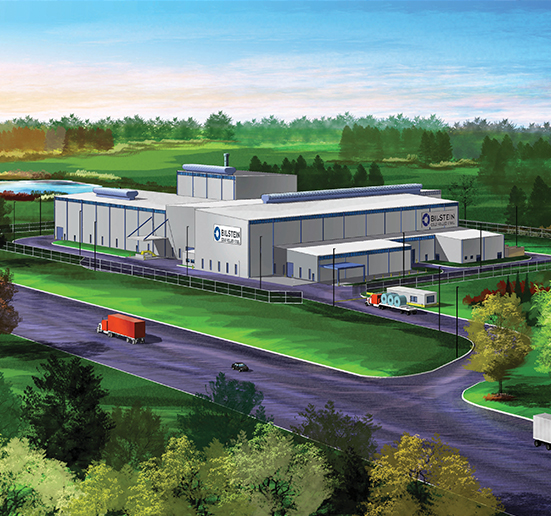

Bilstein Cold Rolled Steel

GSE provided complete engineering services for Bilstein’s first mill constructed outside of Germany. Built on a 61-acre Greenfield site, the facility is strategically located to serve the region’s growing automotive industry. Detailed design for Phase 1 of the facility included a cold rolling mill, eight batch annealing bases and a high-speed slitting line with a 52-foot-deep looping pit, main steel processing facility with adjacent driveways and access, separate access points for truck/employee/visitor traffic, stormwater collection and detention facilities, and planning for a future rail spur. Site and utility design included grading, paving, storm drainage, fire water, domestic water, sewage, electrical, communication lines, rail spur design, and handled permitting with local and state agencies.

SSAB North America

SSAB North America (formerly IPSCO) chose GSE to provide all design services for the new heat treatment and quench line 6 (QL6). The new facility has the capacity to produce 300,000 tons of hardened steel per year. Scope included all utilities, building and equipment foundations, and the 1 million gallon quench system. Additional projects for SSAB include the expansion of quench line 5 (QL5), the addition of a vacuum tank degasser (VTD) to their existing melt shop, and water treatment facility design, along with various maintenance projects throughout the site. GSE has further supported SSAB’s operations and construction with conventional surveying techniques, construction support, aerial mapping/construction tracking capabilities and crane rail alignment surveys.

Braidy Aluminum

GSE provided front-end engineering services in support of Braidy Industry’s planned aluminum mill in Ashland, KY. The front-end design scope required extensive coordination with primary vendors SMS, Ebner, Gautschi, Amova and several more in support of the melting and casting furnaces, hot mill, cold mill, annealing furnaces, CASH Lines and two automated coil handling bays. GSE’s scope included general arrangements, life safety, material handling, building and equipment foundations, medium voltage electrical, process, and fire protection design for the 1.6 million-square-foot facility, budgeted at approximately $1.4 billion.

Nucor Mill Complex

GSE provided complete engineering services for Nucor’s Specialty Cold Mill Complex, which spans over 400,000 square feet and contains a Push/Pull Pickle Line. Specialty steels are becoming increasingly vital in the automotive industry, and this facility is equipped with a six-high reversing cold rolling mill, twenty-four batch annealing furnaces, and a reversing temper mill. The complex will produce advanced high-strength, low-alloy, and motor lamination steel products designed to minimize energy losses when used as core materials for electrical equipment and motors.